Koganei

Elewave

Index Table

Work Size Judging

Position Adjustment

Machine: Semi-conductor inspection machine

Mechanism: Work positioning

Reason of selecting NS Slider:

Decrease down time, tool changing cost

Speed & Force control against work

Round work : Check from 4 directions

Pushing by Air cylinder → Pushing by NS Slider

To remove cable coating, it is necessary to change pushing force.

Ionizer

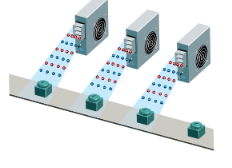

Optimum for removing dust when peeling an LCD protective sheets on car navigation systems, cellular phone, etc.

A normal high-pressure air blower may make a work piece charged with static electricity, which could draw dust. Air Gun Type Ionizer can remove static electricity while blowing away unwanted dust by blowing ion air.

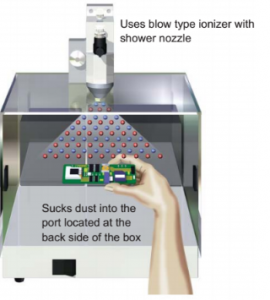

Optimum for the dust removal process before assembling electronic components.

Blow Type Ionizer blows away unwanted dust by blowing ion air while collecting it into the port located at the backside of the box for keeping clean environment.

Uses 2-head type with flexible pipe nozzle to remove static electricity and dust from CDs and DVDs on both sides.

Avoid electrostatic discharging when taking wafers out of their cassettes, and prevents the stored wafer from being drawn to the transfer arm.

Prevents dust from being drawn to the surface of wafers. Prevents the internal patterns from being damaged.

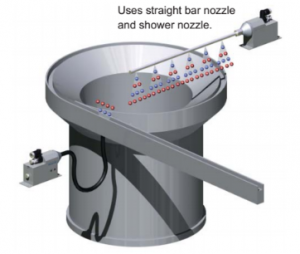

Static electricity is generated due to the friction of parts when parts feeder conveys parts, so parts are drawn to its surface.

Use blow type ionizer to prevent parts from being drawn caused by static electricity. Also, dual use with a fan type is effective against the static electricity removal.

Very low generation of electrical noise ( A measurement value of electric noise: 19 dB V/m or less at 30MHz )

No damage to a device caused by induction electric field from discharging needle.

Removal of static electricity with pin point accuracy ( it is possible to bring the nozzle close to a device )

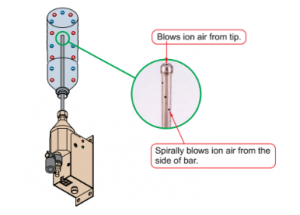

Uses spiral bar nozzle to remove static electricity inside bottle.

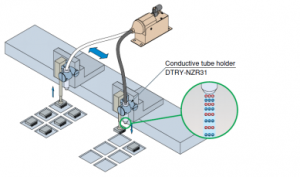

By inserting the tube inside a pipe enables removal of static electricity.

You can make static electricity removal for relatively wide object.

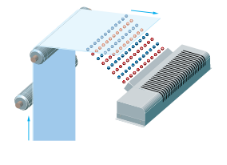

You can remove the static electricity generated when the film leaves the film roller.

You can make static electricity removal from relatively far locations.